MARINE

EMC offers shipboard and in shop electrical and mechanical services to Marine customers.

EMC has the technical experience, skilled and trained craftsperson and discipline Engineering staff; combined with our state of the art facilities to maintain and rebuild/repair your ship and facilities equipment needs.

Our approved QPL program is certified to government requirements.

Marine and Ship Repair Services Comprehensive Capabilities

Electric Motor Services

- Rewinding up through 13,200 VAC using epoxy vacuum pressure impregnation (VPI – 12' Diameter Tank) on all form wound motors through 7KV and B-stage hot pressed coils above 7KV

- Comprehensive machining for shaft repair/replacement, bearing housing repairs, complete internal horizontal and vertical alignment.

- Dynamic balancing of rotating components, typically to ISO 1940 standards G2.5 and 1.0

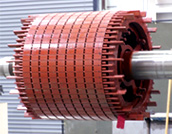

- Replacement of stator laminations with low loss, laser cut laminations

- Rebuilding of squirrel cage rotors, including rotor bar replacement, laminations, replacement and in some cases, complete new rotor manufacturing

- Upgrades of existing motors, such as rewinding for increased HP or changing bearing design/configuration for optimum vibration reliability

- Full voltage no load testing of all motors up through 18,000HP @ 13.2KV

- IEEE 429/NEMA MG-1 Water Submergence test approved on VPI coils

- Dynamometer full load testing up to 2500HP

- Large motor disassembly, reassembly and testing stands

- 50,000 square foot, 3 story high ceiling bay

- 60 ton crane capacity with a 60 foot hook height

- Dynamic balancing to 12.5 tons

- 3.75 MVA power supply with 13.8 KV capability

- Burnout and bake oven

- Vertical and horizontal lathes

- Service Level 1 coatings

Mechanical Services

- Vertical and horizontal pump repair

- Casing repair and re-machining

- Custom design, re-design and machining

- Rotating equipment repair and manufacturing

- New stator and rotor fabrication

- Specialty coating services

- Repair and manufacturing of Babbitt bearings

- Lathes up to 63" x 28" Center to Center

- Vertical Boring Mill up to 7' x 7' x 5' Cube

- Vertical Turret lathe with 10' rotating bed

- Non Destructive testing

Pump Services

- Inspection, Troubleshooting and problem solving

- Turnkey pump removal, transportation, installation, alignment and start-up

- Vibration analysis and laser alignment

- Field Machining

- Complete disassembly, cleaning and inspection

- Comprehensive repairs including remanufacturing OEM parts and components to original or better than original materials specifications

- CMM aided reverse engineering

- Precision dynamic balancing of individual components and rotating assemblies

- Modernization and upgrades including new shafts, bearings, impellers and wear ring materials

- Modernization, repair and upgrades of connected equipment including gearboxes, couplings and motors

- In house media blasting

- Non-destructive testing, including liquid dye penetration, mag particle and ultrasonic

- Engineered coating systems for improved service life and efficiency

- Certified weld program and welders

Switchgear Testing, Repair & Overhaul

- Molded case circuit breakers

- Switchgear and circuit breakers (air & vacuum) up to 15 KV

- Protective relay and instrument testing

- Replacement breakers and pans (new and obsolete)

- Turnkey projects – Switchgear/Transformers

- Start-up services and training

Field Services – Electrical

- Contracting: Master Electrician

- Engineering: Process design, electrical design, estimating and field management

- Preventive and predictive maintenance

- Motor testing

- Infrared thermography

- Troubleshooting: Motors, Generators, Controls, etc.

- Authorized Service Center for Toshiba variable speed drives

Field Services – Mechanical

- Vibration analysis: Monitoring trending and analysis

- Laser alignment

- In-place dynamic balancing

- Mechanical troubleshooting: Pumps, gearboxes, turbines, shafts and spindles

- On-site equipment repairs, removals and reinstallation

Power Distribution Services

Transformer Testing

- Transformer inspection and testing up to 230 KV

- Doble (Power Factor) test of windings and bushings

- Megger insulation and TTR test

- Oil analysis

- Infrared analysis of energized units

Relay Testing

- Testing and calibration of electromechanical and electronic protective relays

- Design and install retrofits of older protection schemes to new microprocessor based protection relays

Full Substation Testing, Service & Repair

- Power circuit breakers, SF6 gas, Vacuum and oil breakers to 230 KV

- Voltage regulators, tap changers

- Control systems (functional testing)

- Acceptance testing, start-up

- Ground grid testing

- KWH meter testing

Storage Capabilities

- Climate controlled storage facility

- Monthly preventative maintenance performed on stored customer equipment

News/Projects/Technical

- EMC safety milestones.

- EMC is going digital!

- EMC maintenance moves online!

- EMC receives radioactive license amendment 7

- EMC awarded HRSD Gold Award!

- Here we grow again!

- EMC has recently expanded its' Engineering capabilities.

- EMC presented award for SKF Certified Rebuilder.

- Baker DX-12 (Motor winding and surge tester)

- EMC acquires XRF Equipment (Thermo Niton XL2 Gold).

- EMC acquires PDMA MCE (Motor Circuit Evaluator).